We provide custom solutions to all our customers and offer complete technical advices that your company can take advantage of.

The application of screws in injection molding machines, compressors, pumps, and other mechanical equipment.

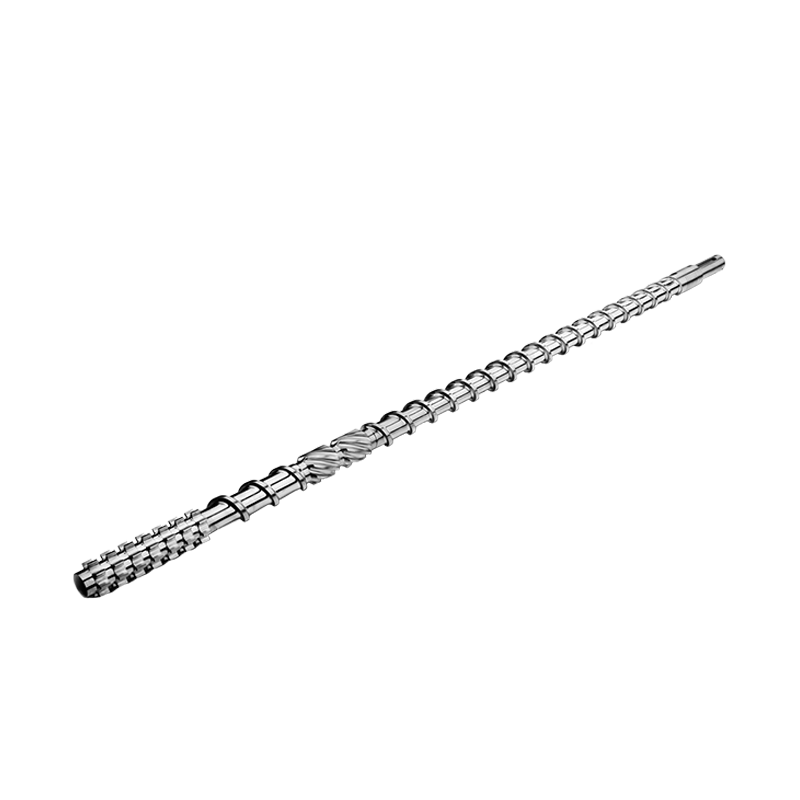

Injection molding machine screw

Screw plays a crucial role in injection molding machines, with the following functions and design features:

Function: The screw is mainly responsible for conveying, compacting, melting, stirring, and applying pressure to plastics. By rotating the screw inside the barrel, the plastic particles are pushed forward and melted by the heat generated by friction. The melted plastic is fully mixed with auxiliary materials such as colorants and fillers under the tooth groove and thread design of the screw, ensuring that various additives in the molded product are evenly distributed. Finally, the screw pushes the melted plastic into the mold and maintains a certain pressure during the injection process to form a molded product.

Design considerations: The design of the screw needs to take into account factors such as the type of plastic, melting temperature, injection pressure, etc. Different types of plastics have different melting points and flowability, so the material, shape, and size of the screw need to be selected according to the characteristics of the plastic. In addition, the magnitude of injection pressure can also affect the design and strength requirements of the screw.

Compressor Screw

In compressors, screws are mainly used to compress gases or refrigerants, and their functions and design features are as follows:

Function: The screw compressor compresses gas by rotating two or more interlocking screws. As the screw rotates, air or refrigerant is gradually compressed and output to the high-pressure area.

Design considerations: The design of screw compressors requires consideration of parameters such as compression ratio, exhaust pressure, and rotational speed. Compression ratio refers to the ratio of gas pressure at the inlet and outlet of a compressor, which determines the compression capacity of the compressor. The exhaust pressure refers to the gas pressure output by the compressor, which needs to be selected according to the specific application scenario. The rotational speed will affect the output power and efficiency of the compressor.

Pump Screw

A screw pump is a type of pump that uses the rotation of a screw to transport liquids. Its functions and design features are as follows:

Function: The screw pump transports liquid from the suction end to the discharge end through the rotation of two or more interlocking screws. This pump is suitable for transporting liquids of various viscosities, including high viscosity oils, syrups, sludge, etc.

Design considerations: The design of a screw pump needs to take into account the properties of the liquid (such as viscosity, corrosiveness, temperature, etc.), flow rate, and pressure parameters. The viscosity of the liquid will affect the speed of the screw and the output power of the pump, while corrosiveness and temperature will affect the material selection and sealing performance of the pump. The flow rate and pressure determine the delivery capacity and working pressure range of the pump.

Other mechanical equipment

In addition to injection molding machines, compressors, and pumps, screws are also widely used in other mechanical equipment such as extruders, mixers, and mixers. In these devices, the role of the screw may include material transportation, mixing, dispersion, etc. The design of the screw needs to be determined based on the specific equipment requirements and material properties. For example, in an extruder, the design of the screw needs to consider factors such as the melting temperature of the material, extrusion speed, and pressure; In mixers and mixers, the shape and size of the screw need to be selected based on the uniformity of material mixing and dispersion effect.